Ferticoat

Overview of Coated Fertilizers

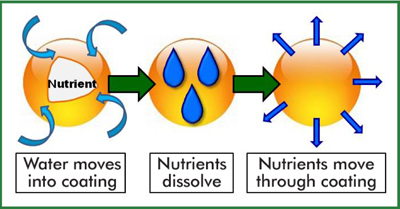

Coatings applied to fertilizer particles help regulate their solubility in soil, which offers environmental, economic, and yield benefits by controlling nutrient release rates.

Production of Coated Fertilizers

A variety of materials are used for coating soluble fertilizers, primarily focusing on granular or prilled nitrogen (N) fertilizers, although multi-nutrient fertilizers are also coated. Urea, a common source of soluble nitrogen, is often the base material for these coated fertilizers.

Early Coating Methods

Elemental sulfur (S) was the first widely used coating. This process involved spraying molten sulfur over urea granules and applying a sealant wax to cover cracks or imperfections. Later improvements included adding a thin layer of organic polymer over the sulfur coating.

Advanced Coating Techniques

Other methods involve reacting various resin-based polymers on the surface of the fertilizer granules. Another technique uses a combination of low-permeability polyethylene polymers and high-permeability coatings. The materials and processes can vary among manufacturers.

The coating’s composition and thickness are adjusted to control the nutrient release rate for specific applications. Nutrient release durations can range from several weeks to several months, as indicated on the product label. Coated fertilizers generally cost more than uncoated ones due to the additional coating process.

Agricultural Uses of Coated Fertilizers

Coated fertilizers are effective in various agricultural and horticultural settings, offering several benefits:

- Reduced Losses: Sustained nutrient release decreases leaching and gaseous losses.

- Cost Efficiency: Fewer applications can lower labor and application costs.

- Improved Seedling Tolerance: Seedlings may better tolerate fertilizers placed close to them.

- Enhanced Growth: Prolonged nutrient release promotes uniform plant nutrition, better growth, and improved performance.

To maximize these benefits, growers should align the duration of nutrient release with the plant’s nutrient uptake periods.

Management Practices

Predicting nutrient release patterns from coated fertilizers across different soil and cropping conditions is complex due to various environmental factors. For example, many coated fertilizers release nutrients more rapidly with increased moisture and soil temperature, while some rely on soil microbial activity. Understanding these mechanisms helps producers get the most value from coated fertilizers.

Some coating materials can be brittle and prone to abrasion, so excessive handling should be avoided to prevent damage.

Non-Agricultural Uses of Controlled-Release Technology

Controlled-release technology has applications beyond agriculture. It is prominently used in pharmaceuticals to allow less frequent dosing while maintaining steady blood concentrations. This technology is also applied in veterinary medicine and pest control.

Source: Nutrient Source Specifics (No. 20), International Plant Nutrition Institute.

There are no reviews yet.